Exploring the Potential of PCB Manufacturing Services: An Extensive Handbook

Introduction to PCB Manufacturing Services

PCB (Printed Circuit Board) manufacturing services play a crucial role in the production of electronic devices. Whether it’s a smartphone, a computer, or a medical device, PCBs are at the heart of modern electronics. This article delves into the intricacies of PCB manufacturing services, highlighting their importance, processes involved, benefits, and future trends.

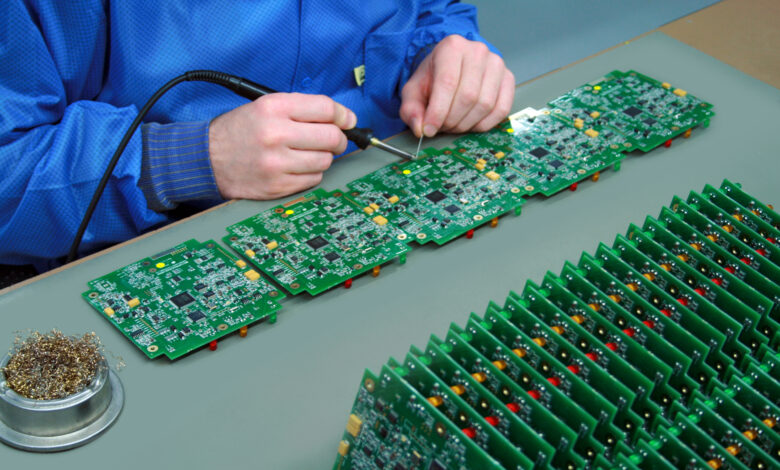

Understanding PCB Manufacturing Process

The PCB manufacturing process involves several stages, starting from design to assembly. It begins with the design stage where engineers layout the circuitry, followed by material selection, printing, etching, drilling, plating, assembly, and testing.

Importance of Quality Assurance in PCB Manufacturing

Quality assurance is paramount in PCB manufacturing to ensure the reliability and functionality of electronic devices. Rigorous testing and inspection procedures are implemented at various stages of production to identify and rectify any defects.

Benefits of Outsourcing PCB Manufacturing Services

Outsourcing PCB manufacturing services offers numerous benefits, including cost savings, access to advanced technology, faster turnaround times, and scalability.

Factors to Consider When Choosing PCB Manufacturing Services

When selecting a PCB manufacturing service provider, factors such as quality standards, reputation, experience, capabilities, and cost should be carefully evaluated.

Types of PCB Manufacturing Services Available

PCB manufacturing services can be categorized into prototype, low-volume, and high-volume manufacturing, each catering to different requirements and production scales.

Trends in PCB Manufacturing Services

Advancements in technology, such as additive manufacturing, flexible electronics, and IoT integration, are shaping the future of PCB manufacturing services.

Cost Considerations in PCB Manufacturing Services

Cost is a significant consideration in PCB manufacturing, influenced by factors like material costs, labor, equipment, and volume of production.

Environmental Impact of PCB Manufacturing

Efforts are being made to reduce the environmental footprint of PCB manufacturing through sustainable practices, recycling initiatives, and eco-friendly materials.

Future Outlook for PCB Manufacturing Services

The future of PCB manufacturing services looks promising, with continued innovation driving efficiency, reliability, and sustainability.

Case Studies: Successful Implementation of PCB Manufacturing Services

Several case studies demonstrate the successful implementation of mktpcb.com services in various industries, showcasing their impact on product development and market competitiveness.

Challenges Faced in PCB Manufacturing Services

Challenges such as supply chain disruptions, component shortages, and technological complexity pose significant hurdles in PCB manufacturing.

Innovations in PCB Manufacturing Technology

Innovations like 3D printing, nanotechnology, and AI-driven design are revolutionizing the PCB manufacturing landscape, offering new possibilities for efficiency and customization.

Conclusion

In conclusion, PCB manufacturing services play a critical role in the production of electronic devices, ensuring reliability, functionality, and innovation. As technology advances and market demands evolve, the need for efficient and reliable PCB manufacturing services will only continue to grow.

FAQs About PCB Manufacturing Services

1. What is PCB manufacturing?

PCB manufacturing is the process of producing printed circuit boards used in electronic devices, involving various stages such as design, material selection, printing, assembly, and testing.

2. Why is quality assurance important in PCB manufacturing?

Quality assurance is essential in PCB manufacturing to ensure the reliability and functionality of electronic devices, minimizing defects and ensuring compliance with industry standards.

3. What are the benefits of outsourcing PCB manufacturing services?

Outsourcing PCB manufacturing services offers benefits such as cost savings, access to advanced technology, faster turnaround times, and scalability.

4. How do environmental considerations impact PCB manufacturing?

Environmental considerations influence PCB manufacturing practices, driving initiatives for sustainability, recycling, and the use of eco-friendly materials to minimize environmental impact.

5. What are some emerging trends in PCB manufacturing services?

Emerging trends in PCB manufacturing services include additive manufacturing, flexible electronics, IoT integration, and advancements in materials and design technologies.